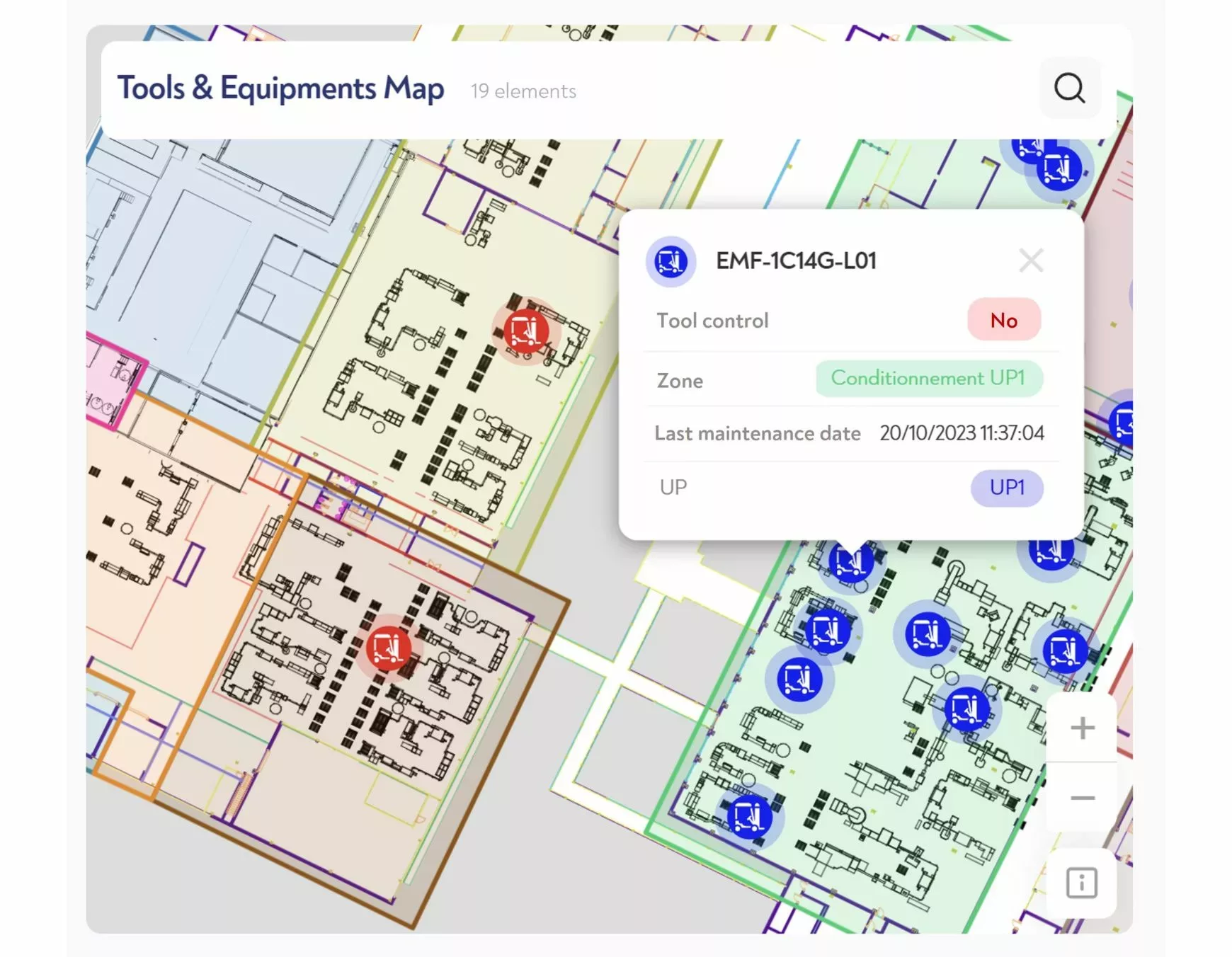

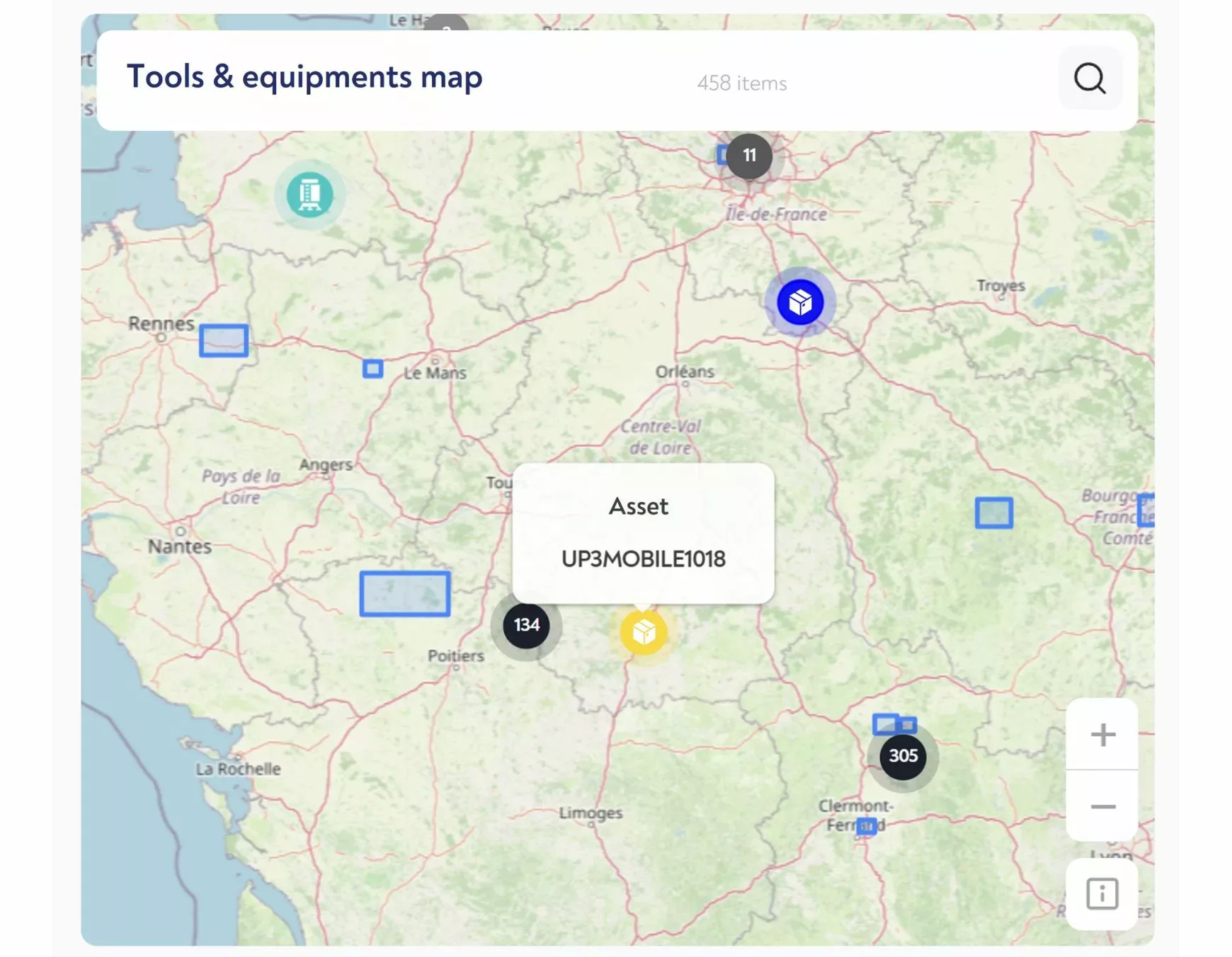

Use it to geolocate and visualize your WIP and assets inside and/or outside the plant on a dynamic map, in real time.

This map enables you to find your WIP and filter your field datas.

ROBIN SMART TRACKING is the first level of service of SaaS ROBIN, to be combined with our indoor or outdoor geolocation solution.

This service level gives you access to the following KPI modules:

Thanks to this full track and trace solution: anticipate risks (delivery delays, bottlenecks, asset immobilization) and waste sources.

We offer a wide IoT portfolio (sensors and connected devices) and our service is based on our software and geolocation technologies deployment on your industrial plant.

We choosed to be tech-agnostic (GPS, RFID, 4G, 5G, LoRa, NB-IoT, LTE-M….) in order to best meet our customers’ expectations and their specific business and field requirements.

The ROBIN Smart Tracking solution is available for a wide range of industrial plants and various sectors (aeronautics, automotive, glass production, cosmetics, MedTech, chemicals, etc) whose complexity we understand (high, ATEX or highly metallic environments, etc.).

All our KPI modules are scalable and fully configurable in no-code – i.e., no line of code required.

A wide range of use cases can be addressed:

You can thus focus on your best added value and delegates the remaining tasks to your software ROBIN!

Ask for a free demo

Use it to geolocate and visualize your WIP and assets inside and/or outside the plant on a dynamic map, in real time.

This map enables you to find your WIP and filter your field datas.

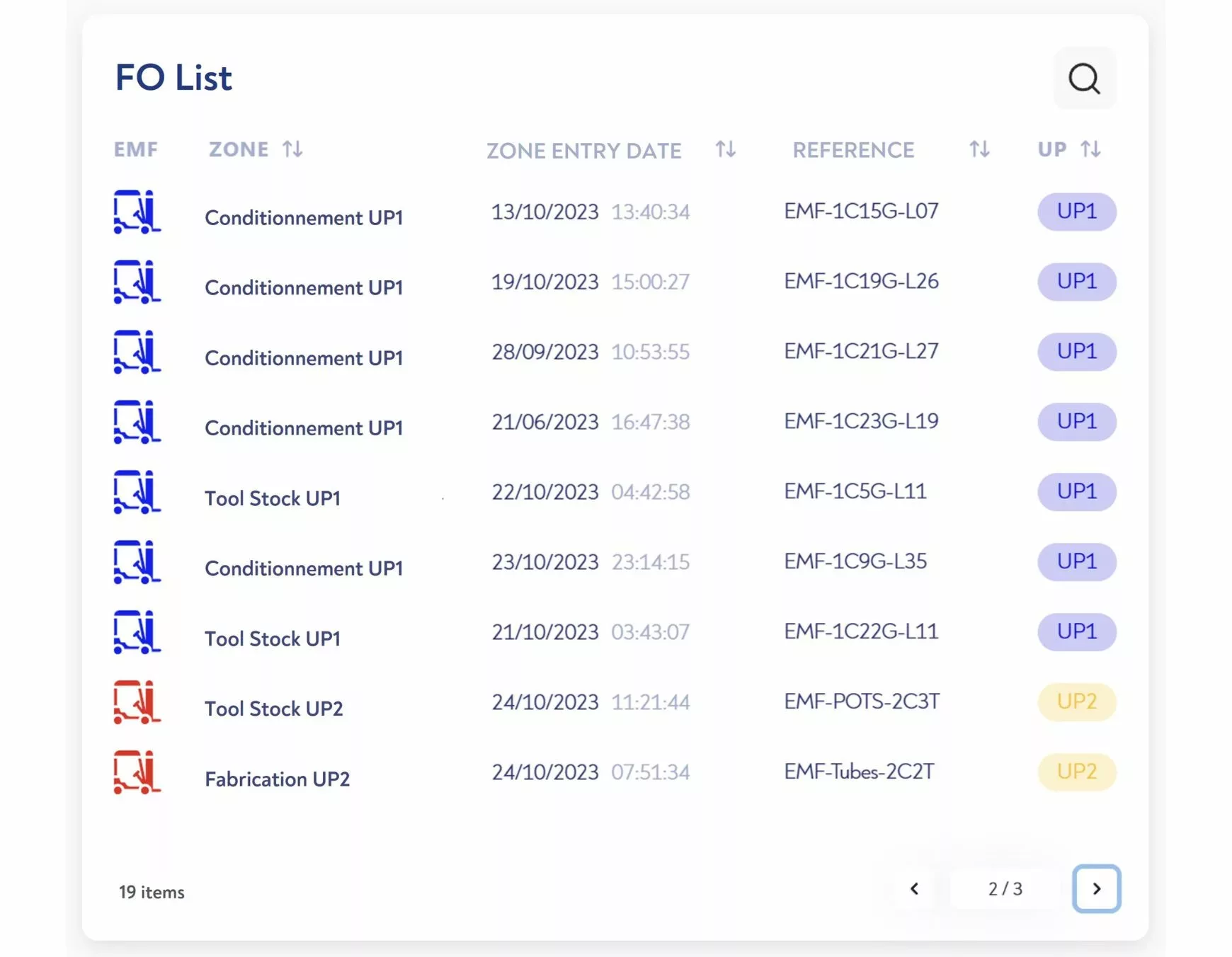

Customized tables are necessary to our customers for production quality status management, lead times and production overall datas.

Your datas are updated, easy to export in a single click, just a click away and in real time.

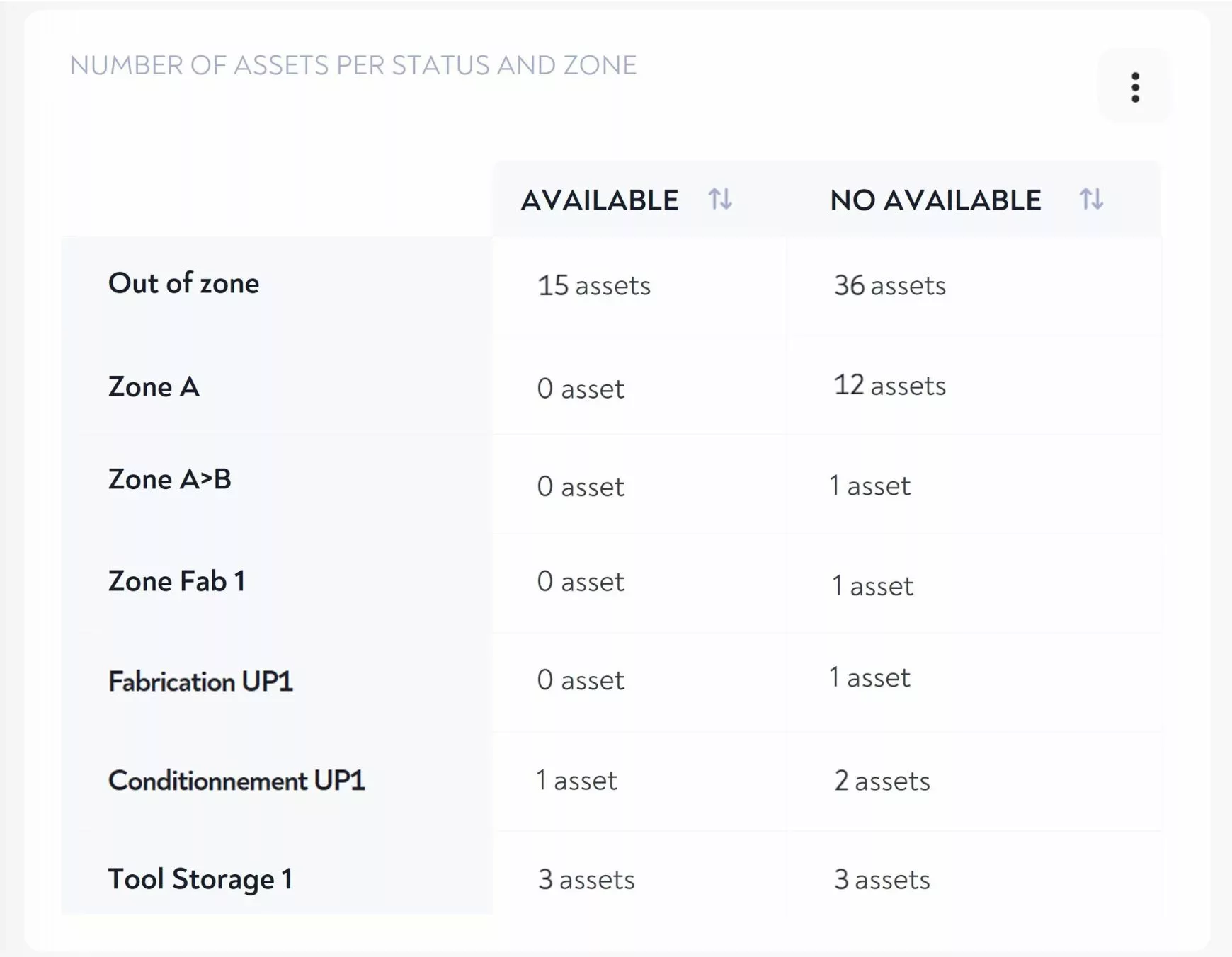

With the cross-tabulation module, you can observe your WIP according to two production statuses, and save time in your analysis.

ROBIN Smart Tracking gives you access to a series of advanced graphs: histograms, pie charts, gauges for in-depth analysis of the status of your work-in-progress over time.

With ROBIN Smart Tracking, you can automatically detect when a product or work-in-process is out of zone or enters a specific area. Thanks to geofencing, production statuses (hygiene statuses, entry of a container into a quality control zone, etc.) are automatically updated according to their location.

Ensure a reliable tracking of your containers (IBCs, tote containers, trestles, tanks, etc) and work-in-process thanks to our full track and trace solution based on customized IoT technologies deployed rapidly at your industrial plants.

Save time with indoor geolocation and outdoor geolocation of your containers and parts throughout your supply chain*.

*supply chain.

Get a complete profile of your WIP and identify process errors.

Eliminate inventory and stock discrepancies. Keep track of all your equipment inventories to optimize allocated resources.

Keep track of your production and work-in-progress in real time, and interact with different work teams. View your material status, production and buffer stock situation.